Composting in the Subarctic – Operations

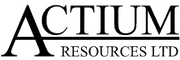

The Actium compost drums are used in a variety of climates. In the tropical and subtropical climates, the composter is used year-round. In temperate climates, the Actium Batch Compost Drum can be used year-round because the drum is insulated. However, the decaying process can be slowed where winter temperatures are below freezing for a prolonged […]