Greens and Browns: Composting Input Management

Actium Composting equipment allows for environmentally sustainable disposal and reuse of organic materials in the form of compost. The program I work with invested in an Actium Batch Composter Drum, to primarily create local fertilizer for subarctic community gardens located in Fort Albany First Nation, Ontario, Canada. As a secondary benefit, the Actium composter reduced the amount of organic waste accumulating in the Fort Albany First Nation’s landfill. Community gardens are one of many types of operations that use Actium Composting Equipment. Internationally there are operations in hospitality, recreation, agriculture, landscaping, and education that use Actium Composting equipment.

Each of these mentioned operations has a desired organic waste to be reduced. For the Fort Albany First Nation gardening program, geese remnants and fruit and vegetable scraps were the main organic wastes to be reduced– both of these materials are known as “greens”. These “green” materials need to be mixed with “brown” organic materials to have the hot composting process run efficiently. This article aims to explain why “browns” need to be added with “greens” when composting, as well, to provide some general tips on composting input management.

The greens and the browns

Labelling organic materials as “greens” or “browns” helps differentiate types of materials that have a high carbon to nitrogen ratio (C:N) with materials containing a low C:N. Organic materials contain an assortment of elements, but carbon and nitrogen are the most important elements for controlling microbial activity. Carbon provides the microbes with energy, while microbes use nitrogen for protein production. All organic materials contain more carbon than nitrogen, though the ratio between these two elements will differ depending on the organic type. Organic materials with a low C:N ratio are considered “greens” – the C:N for “greens” are 30:1 or less. Some examples of “greens” include vegetable scraps (C:N = 11:1), grass clippings (C:N = 15:1), deadstock (C:N = 5:1), and coffee grounds (C:N = 14:1). Materials that are considered “browns” have a high C:N – greater than 30:1 – such as, straw (C:N = 53:1), wood shavings (C:N = 226:1), paper (C:N = 129:1), and dried leaves (C:N = 47:1). A quick web browser search for “composing greens and browns” will result in resources that share lists of organic materials – and their C:N – divided into “greens” and “browns” categories.

Mixing the browns with the greens

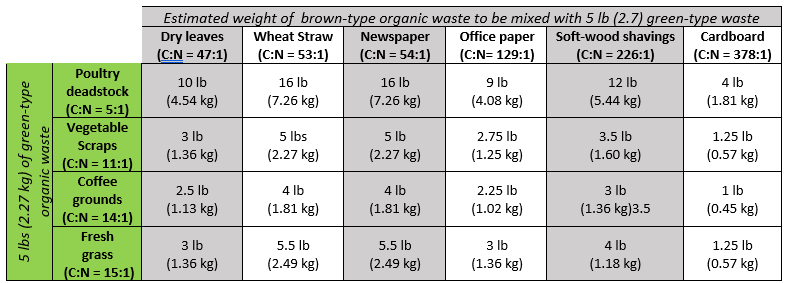

Every addition of organic materials into a composter drum will influence the decomposing activity, and effect the C:N ratio of the compost. Knowing the C:N for each organic type added to the Actium batch composter is recommended. As well, it is suggested to aim for a compost C:N to range between 20:1 to 40:1, however the ideal compost C:N ratio is between 25:1 to 30:1. Maintaining a compost C:N of 25:1 to 30:1 helps sustain high temperatures for hot composting, also it is the most balanced diet for the best performance of decomposers. If too many “greens” are added into the compost drum, then the overall compost C:N becomes too low, releasing offensive odours, and slowing decomposition. If too many “browns” are added, decomposition will also slow down. There are some compost mix calculators available online to help determine how much green-type and brown-type materials are needed to achieve the ideal compost C:N. Below is a table briefly indicating how much (by weight) of a brown-type material is needed for 5 lbs (2.27 kg) of a green-type material. For example, the addition of 5 lbs of vegetable scraps into a composter drum, requires around 2.75 lbs of shredded office paper for the compost mix to have a calculated C:N of 25-30:1.

Table: Different types of brown-type organic materials and the weight needed of each brown-type to achieve a compost C:N ratio of 25-30:1 when mixed with 5lbs of a green-type of organic waste.

Input-management tips for Actium Batch Composting Drums

- Create a log to monitor the quantity and type of organics added per week (also monitor compost temperature and moisture levels).

- Do not add more than 50 lb (23 kg) per day of organic materials to the Actium Batch Composting Drum.

- Turn the compost drum every time organics are added, or at least once a week during times when there are no organic additions.

- If the compost starts to smell, add more browns – smells indicate that the nitrogen content of the compost is too high.

- Shred or chop organic materials to increase surface area and to improve the rate of decomposition .

- Prevent any non-organic matter from entering the compost drum such as twist-ties, plastics, glass, metal, or other non-compostable waste as this will reduce the quality and grade of the compost.

Double-checking compost quality and performance

Those who are interested in knowing the exact C:N ratio of a finished compost batch, samples can be sent to a compost analysis service. These services – found online or locally – often can provide other compost information such as pH, nutrient content, microorganism populations, and contaminant concentrations. The price of compost analysis differs from each company and by the number of samples and tests requested. If compost is to be tested, it is recommended to use a well-mixed sample and to analyze more than one sub-sample to get a better representation of what is occurring in the finished compost. Knowing the actual C:N ratio (as well as other compost analysis results) can be helpful to adjust compost management for best performance.